Uncover Galvanized Steel Shops in Pampa, Texas

December 19, 2024

Uncover Galvanized Steel Shops in Mont Belvieu, Texas

December 19, 2024Galvanized steel shops in Lancaster, Texas, play a pivotal role in the local economy and are essential for various industrial applications. Galvanized steel is a versatile material that has been treated with a protective zinc coating to enhance its durability and resistance to corrosion.

This process helps extend the lifespan of the metal, making it resistant to rust and other forms of wear from environmental elements. The inherent benefits of galvanization have made galvanized steel a popular choice across multiple sectors, including construction, agriculture, automotive manufacturing, and more.

The characteristics that define galvanized steel-such as its strength and longevity-make it an ideal solution for many structural applications. Industries often rely on this material not only for its physical properties but also for its cost-effectiveness over time. For instance, using galvanized steel can lead to lower maintenance costs due to its resistance to deterioration. From guardrails along highways to structural components in commercial buildings, galvanized steel is ubiquitous in today’s infrastructure.

The Galvanized Steel Industry in Lancaster, Texas

Overview of the Local Steel Industry

Lancaster, Texas, has established itself as a significant hub for the galvanized steel industry, playing a crucial role in both regional and national markets. The city’s strategic location in North Texas provides easy access to major highways and transportation networks, facilitating efficient distribution of galvanized steel products across the state and beyond.

This accessibility has attracted numerous businesses specializing in galvanized steel shops, fostering growth and stability in the local economy. Additionally, these shops create a wide range of job opportunities, from production roles to administrative positions, further invigorating Lancaster’s economic landscape.

Key Players in the Galvanized Steel Market

Within Lancaster’s vibrant industrial scene, various key players contribute to the galvanized steel market. Prominent galvanized steel shops employ advanced techniques in fabrication and processing to ensure high-quality products that meet diverse consumer needs. Local businesses not only cater to large-scale construction projects but also serve smaller industries requiring customized solutions.

Collaboration among these companies enhances innovation across product lines while maintaining competitive pricing structures that benefit clients across different sectors. As demand for durable materials grows-especially within construction, automotive, and agricultural industries-these key players are poised for continued success.

Economic Contributions of Galvanized Steel Shops

The presence of galvanized steel shops has generated significant economic benefits for Lancaster, Texas. These businesses contribute actively to the city’s tax base while supporting ancillary industries such as transportation, logistics, and retail through their procurement needs. Furthermore, local suppliers that offer raw materials play an integral role in sustaining this sector by providing quality inputs necessary for manufacturing processes.

As a result of these interconnected relationships within the community, Lancaster not only boosts its own economy but also strengthens regional networks vital for long-term industry viability and community growth. Investing in galvanized steel resources ensures lasting durability for infrastructure throughout the area while reaffirming Lancaster’s position as a leading contributor to Texas’s industrial landscape.

Key Features of Galvanized Steel Shops

Infrastructure and Facilities

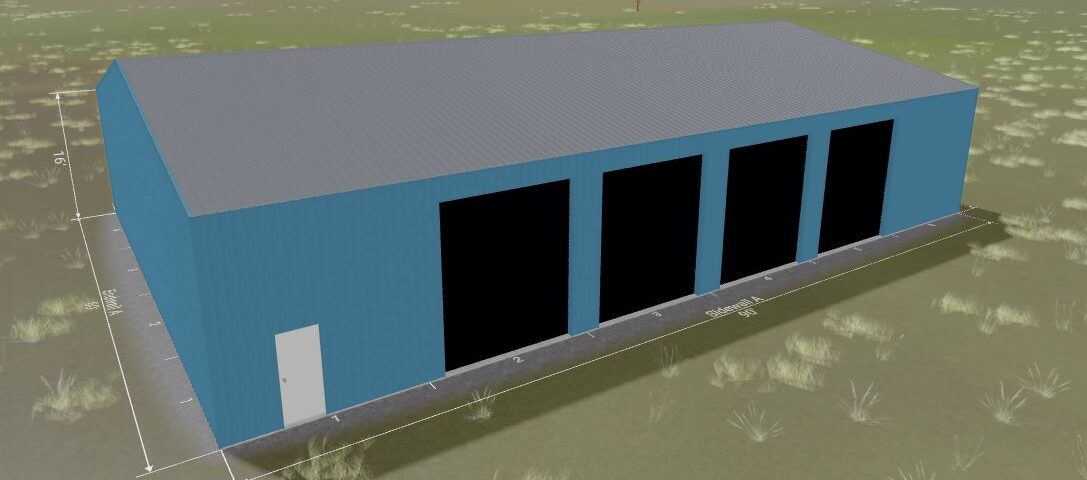

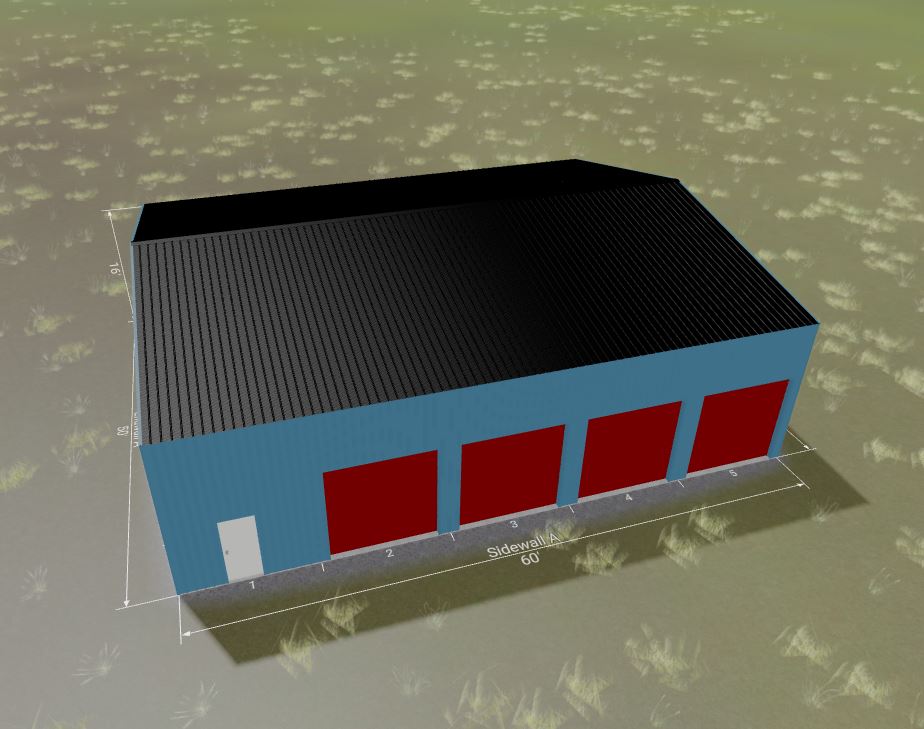

Galvanized steel shops in Lancaster, Texas, boast a well-designed infrastructure geared towards optimizing production efficiency and ensuring high-quality outputs. These facilities typically feature large manufacturing bays equipped with state-of-the-art machinery that facilitate the various stages of galvanization-ranging from surface preparation to zinc application.

The layout of these shops is strategically organized to streamline workflows; raw materials enter one end, undergo extensive processing, and leave as finished products ready for distribution. Safety protocols are thoroughly integrated into the physical design to safeguard workers while maintaining compliance with industry regulations.

Additionally, many galvanized steel shops incorporate specialized zones for research and development, allowing for continuous improvement and innovation in their processes. This commitment to facility enhancement ensures that shops can adapt to changing market demands and technological advancements while providing a safe work environment.

Equipment and Technology

The equipment utilized in galvanized steel shops plays a pivotal role in determining the quality of the final product. Modern galvanized steel shops in Lancaster are outfitted with advanced machinery including hydraulic press lines, automatic dip tanks, and robotic arms for precision handling of materials. The automation not only increases production speeds but also reduces human error during critical processes such as cutting and coating.

Furthermore, investing in new technologies such as online monitoring systems allows manufacturers to keep track of temperature ranges, thickness levels, and other critical parameters throughout the galvanization process. By incorporating these innovations into their operations, galvanized steel shops can ensure superior product durability while minimizing defects associated with traditional methods.

The Importance of Skilled Workforce

While innovative technology is crucial for product excellence, the role played by a skilled workforce cannot be overstated within galvanized steel shops in Lancaster. Skilled technicians are essential for operating complex machinery safely and efficiently; they handle everything from routine maintenance to troubleshooting unexpected issues that may arise during production runs. Their expertise contributes significantly to maintaining high standards that clients expect from top-tier suppliers.

Moreover, continuous training programs empower employees to stay ahead of industry trends and effectively utilize emerging technologies aligned with environmental sustainability initiatives. Building an adept workforce not only supports operational success but enhances overall outcomes-fostering confidence among clientele in the reliability of products supplied by local galvanized steel businesses.

Types of Products Offered by Galvanized Steel Shops

Galvanized steel shops in Lancaster, Texas, play a crucial role in providing a wide range of products tailored to meet the diverse needs of various industries. Among the common offerings are galvanized steel pipes, which are essential for plumbing and other construction projects due to their durability and resistance to rust.

These pipes are typically produced in various diameters and lengths, allowing for flexibility in application from residential buildings to large-scale industrial setups. Additionally, galvanized sheets and roofing materials are favored for construction projects where protection against environmental factors is necessary; these products boast enhanced longevity, making them a smart investment.

Another key product category includes galvanized steel beams and columns, widely used in structural applications. These components provide necessary support in commercial and residential buildings alike. Customization options also abound; clients can often request specific sizes or specifications suited to their particular projects. For instance, businesses involved in the manufacturing sector might require unique cut dimensions or thicknesses that accommodate specialized processes. This level of customization ensures that customers receive products aligned with their operational requirements.

A growing trend within galvanized steel production is the focus on eco-friendly practices and materials. Many galvanized steel shops now emphasize sustainability by sourcing raw materials locally where possible and employing energy-efficient technologies during manufacturing.

Additionally, the lifecycle of galvanized steel products demonstrates long-term environmental benefits; they often have long service lives, reducing the need for frequent replacements and minimizing overall waste. With innovations continuously emerging within this industry-ranging from advances in galvanizing technology to new product designs-galvanized steel shops in Lancaster remain pivotal not only for local economies but also for environmentally conscious initiatives throughout Texas.

| Product Type | Description |

|---|---|

| Galvanized Steel Pipes | Durable piping solutions used in plumbing and construction. |

| Galvanized Sheets | Used primarily for roofing and protective structures. |

| Structural Beams/Columns | Provide essential support in commercial and residential buildings. |

Benefits of Choosing Galvanized Steel

Galvanized steel offers an array of benefits that make it a preferred choice for various applications across industries. One of the most significant advantages is its outstanding durability, which stems from the galvanization process. This coating involves immersing steel in molten zinc, creating a protective barrier that effectively resists rust and corrosion.

The longevity of galvanized steel reduces the need for frequent replacements, saving both time and money in maintenance costs. This aspect is particularly beneficial for businesses operating in environments prone to moisture or harsh weather conditions, where unprotected steel would deteriorate more quickly.

Another important benefit to consider when choosing galvanized steel is its cost-effectiveness. While the initial investment might be slightly higher compared to non-galvanized alternatives, the long-term savings due to reduced maintenance and replacement significantly outweigh these costs. As industries increasingly focus on lifecycle analysis when selecting materials, the economic advantages of using galvanized steel become even clearer. Here are some key points regarding its cost-effectiveness:

- Reduced Maintenance Costs: With longer-lasting protection against corrosion, businesses save on repair and upkeep expenses.

- Extended Lifespan: Galvanized steel products typically last much longer than uncoated options, ensuring better value over time.

- Fewer Replacements Needed: The resilient nature of galvanized steel means that users won’t need to replace materials as frequently.

In addition to financial factors, utilizing galvanized steel also has environmental benefits that align with today’s sustainability goals. The production processes involved can be designed to minimize waste and energy consumption.

Furthermore, since galvanized steel can be recycled multiple times without losing its inherent properties, it contributes positively towards reducing landfill waste and conserving natural resources. For organizations seeking sustainable solutions, opting for materials like those offered by galvanized steel shops in Lancaster, Texas not only supports green practices but also supports local economies through job creation and material sourcing within the community.

How to Select a Galvanized Steel Shop in Lancaster

When selecting a galvanized steel shop in Lancaster, Texas, clients should consider several critical factors to ensure they partner with a reputable and efficient provider. One vital aspect is the shop’s certifications and industry standards compliance.

Shops that hold certifications from recognized organizations not only indicate adherence to quality but also demonstrate their commitment to safety and environmental practices. This level of credibility is crucial when making decisions, especially for large-scale projects where specifications and compliance can impact the overall success.

Another important consideration is the reputation of the galvanized steel shop within the community and industry. Online reviews, word-of-mouth recommendations, and case studies can provide insights into a shop’s reliability and performance history.

Local businesses often build long-term relationships based on trust, so it’s beneficial to consult peers or industry experts for personal experiences with specific shops in Lancaster. Evaluating customer service is equally essential; a responsive team that provides timely updates on orders, has clear communication policies, and offers support during installation can significantly enhance client satisfaction.

Lastly, potential customers should assess product quality through direct inquiries or site visits. Many galvanized steel shops employ rigorous quality control measures, but it’s beneficial for clients to understand these processes better. Inquire about their production techniques, material sourcing, and any testing protocols employed before shipment. Additionally, engaging with staff about customization options allows clients to see how flexible a provider is regarding specifications such as size and finish tailored for unique projects.

| Key Considerations | Details |

|---|---|

| Certifications | Compliance with industry standards ensures quality and safety. |

| Reputation | Check online reviews and seek recommendations from local businesses. |

| Customer Service | Responsive communication improves client satisfaction. |

| Product Quality | Assess production processes and inquire about customization options. |

Trends and Innovations in the Galvanized Steel Sector

The galvanized steel sector is experiencing a wave of trends and innovations that are shaping its future, particularly in regions like Lancaster, Texas. One significant trend is the growing emphasis on sustainable production methods. As environmental consciousness continues to rise, galvanized steel shops are focusing on reducing their carbon footprints.

This includes adopting more energy-efficient processes and utilizing recycled materials wherever possible. Companies are increasingly investing in facilities that incorporate solar power or other renewable energy sources, targeting a greener future without compromising the quality and durability of their products.

Another noteworthy innovation in the galvanized steel industry involves advancements in coating technologies. New techniques have emerged that enhance the adhesion and longevity of the galvanization process. For instance, several companies now utilize advanced alloying techniques to improve corrosion resistance even further, extending the lifespan of galvanized products.

This innovation allows manufacturers to offer longer warranties on their products while significantly reducing maintenance costs for end-users. Galvanized steel shops in Lancaster, Texas, are at the forefront of these advancements, striving to provide customers with high-performance materials tailored for various applications.

Furthermore, digital technology is revolutionizing how galvanized steel shops operate by streamlining production and enhancing customer interaction. Automation has become integral to maintaining consistency and efficiency across manufacturing lines. Many businesses have also adopted Customer Relationship Management (CRM) systems that allow better management of client projects and inquiries.

These technological upgrades ensure timely delivery and greater transparency throughout the procurement process, making it easier for clients to track order progress and communicate with suppliers about specific needs or adjustments needed for their projects. With these developments redefined by technology and sustainability at core values, the galvanized steel sector in Lancaster is poised for significant growth while staying true to its commitment to quality service and product excellence.

Conclusion

The future of galvanized steel shops in Lancaster, Texas, appears to be bright and full of potential. As industries increasingly prioritize durability, cost-effectiveness, and environmental sustainability, the demand for galvanized steel continues to grow.

This trend is particularly significant for local economy contributors, as galvanized steel plays a key role in a wide array of applications ranging from infrastructure projects to manufacturing processes. The unique characteristics of galvanized steel-its resistance to corrosion and extended lifespan-make it an essential material that will likely see increased usage across various sectors.

As we look towards the future, the galvanized steel industry in Lancaster is poised for growth fueled by innovation and continuous improvement. New technologies are enhancing production capabilities while also addressing ecological concerns regarding manufacturing processes. Innovations such as advanced galvanizing techniques and automation are setting the stage for higher efficiency and improved product quality. These advancements not only bolster the operational aspect of galvanized steel shops but also help minimize environmental impacts, aligning with global trends towards sustainable practices.

For anyone considering a project that requires high-quality materials, exploring the offerings of galvanized steel shops in Lancaster, Texas can be a valuable starting point. With numerous players committed to providing top-notch products tailored to individual needs, there’s no shortage of options available for consumers looking for reliable solutions.

Whether you are planning an industrial construction project or seeking materials for home renovation, engaging with local businesses dedicated to this segment guarantees access to expert advice and superior customer service.

The vibrant landscape of insulated commercial collaboration further supports community development while satisfying evolving market demands. Now is the time for both individuals and businesses to embrace the benefits of galvanized steel-an investment that promises value now and into the future.