Uncover Galvanized Steel Cabins in Fort Lupton, Colorado

January 3, 2025

Discover Galvanized Steel Cabins in Universal City, Texas

January 3, 2025Galvanized steel shops in Highland Park, Texas, represent a vital segment of the industrial landscape, offering innovative solutions for various applications. Galvanized steel is a type of steel that has undergone a process to coat it with zinc, which significantly enhances its resistance to rust and corrosion.

This key characteristic makes it an invaluable resource across multiple sectors, including construction, automotive, and agriculture. The durability and longevity of galvanized steel ensure that it remains a preferred material in environments where exposure to moisture and corrosive elements is common.

The significance of using galvanized steel cannot be overstated; its protection against the elements leads to lower maintenance costs and extended lifespans for structures and products made from it. Industries that prioritize sustainability and cost-effectiveness often turn to galvanized steel due to its impressive performance characteristics. In addition to its functional benefits, using this material can positively impact project timelines and budgets by reducing the frequency of replacements or repairs.

In Highland Park, Texas, galvanized steel shops have become indispensable partners for businesses looking to source high-quality materials tailor-made for their needs. The combination of local resources-ranging from skilled labor to access to modern technology-facilitates a robust environment for steel fabrication.

As industries grow and evolve in this region, the importance of these shops continues to rise as they cater not only to local demands but also contribute significantly to the economy through job creation and technological innovation in metal production processes.

Why Highland Park, Texas Is a Hub for Steel Fabrication

Highland Park, Texas, has established itself as a prominent hub for steel fabrication, particularly in the realm of galvanized steel. One of the primary catalysts for this development is its strategic geographic location. Situated near major transportation arteries, Highland Park provides easy access to suppliers and customers alike.

This advantageous positioning not only facilitates efficient logistics for steel shops but also draws businesses and workers from surrounding areas seeking opportunities within the burgeoning industry. Such accessibility enhances the growth potential for galvanized steel shops in Highland Park, Texas, allowing them to thrive in a competitive marketplace.

Local Resources and Skilled Labor

The success of galvanized steel fabrication in Highland Park can also be attributed to the abundance of local resources and a skilled labor force. The area benefits from a robust supply chain that includes raw material providers, which is crucial for producing high-quality galvanized steel products.

Furthermore, numerous vocational schools and training programs contribute to cultivating skilled workers who are well-versed in modern fabrication techniques and safety standards. This combination of accessible resources and dedicated talent ensures that galvanized steel shops maintain high production standards while continuously innovating their processes to enhance efficiency.

Economic Impact on the Region

The presence of galvanized steel shops in Highland Park brings significant economic benefits to the region. In addition to providing jobs for local residents, these establishments contribute to an increased tax base which supports community infrastructure and services.

The multiplier effect means that those employed at these shops often spend their wages locally, stimulating further economic activity within Highland Park. Additionally, by attracting companies related to construction, manufacturing, and agriculture that rely on specially fabricated materials, the region fosters a diverse industrial ecosystem that promotes long-term economic sustainability and growth in various sectors reliant on high-quality galvanized steel products.

Types of Galvanized Steel Products Available

Overview of Common Products Made From Galvanized Steel

Galvanized steel is celebrated for its versatility, making it a favored material across various sectors. Its protective zinc coating effectively wards off rust and corrosion, ensuring longevity and reliability. Among the most common products derived from galvanized steel are pipes and tubing, which serve critical functions in construction, plumbing systems, and structural applications.

Additionally, galvanized steel sheets are extensively utilized for manufacturing roofing materials, siding panels, and other exterior components that require durability against environmental elements. Producers in Highland Park benefit from an established supply chain that caters to diverse product demands.

Specific Applications in Construction, Automotive, and Agriculture

Within the construction industry, galvanized steel plays an essential role in fabricating foundational structures such as beams and trusses due to its strength-to-weight ratio. Builders often favor it for framework as well as safety handrails because they require both robustness and resistance to weathering.

The automotive sector leverages galvanized steel for body parts that must endure exposure without succumbing to deterioration; this adds value to vehicles over their lifespan while reducing maintenance costs for consumers. Furthermore, in agriculture, galvanized steel is integral for creating equipment like fencing materials and storage tanks where durability against harsh outdoor settings is paramount.

Customization Options Offered by Galvanized Steel Shops

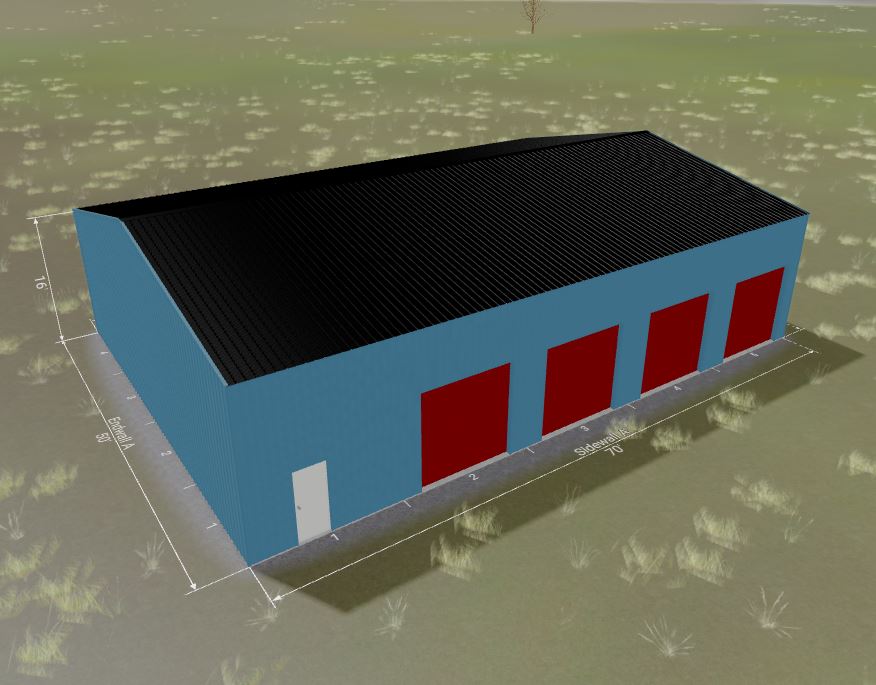

One significant advantage of working with galvanized steel shops in Highland Park, Texas, is the wide array of customization options available for clients. Many shops provide tailor-made solutions based on specific project requirements or preferences. This includes varying thicknesses of materials depending on the load-bearing needs or aesthetic modifications that suit individual architectural styles.

Moreover, local shops often facilitate quick turnaround times on orders due to streamlined processes honed through experience in managing client specifications efficiently. These tailored offerings not only support local businesses but also ensure that customers receive high-quality products ideally suited to their unique applications.

Features of Galvanized Steel Shops in Highland Park

Galvanized steel shops in Highland Park, Texas, are distinguished by a unique combination of specialized equipment and skilled labor dedicated to producing high-quality galvanized products. One prominent feature of these shops is the advanced technology employed in the galvanization process itself.

State-of-the-art systems allow for efficient dipping and coating methods that ensure an even layer of zinc on the steel surface, providing superior corrosion resistance. Additionally, many of these facilities utilize automated machinery for cutting, shaping, and welding, helping to enhance precision while improving production speed.

The workforce at these galvanized steel shops also contributes significantly to their reputation for excellence. With a rich pool of local talent trained in metallurgy and fabrication techniques, Highland Park has become a breeding ground for skilled artisans who understand not only the principles behind steelwork but also the specific needs of various industries.

From construction projects needing structural support beams to agricultural applications requiring durable fencing options, knowledgeable staff members are available to provide tailored solutions that meet customer demands.

Furthermore, commitment to quality standards is another defining characteristic of galvanized steel shops in Highland Park. Many establishments adhere to ISO certification requirements or similar regulatory benchmarks that ensure consistency and reliability across their product offerings.

This commitment extends beyond just compliance; it also reflects a dedication to customer satisfaction through routine inspections and adherence to best practices within the manufacturing process. Alongside this focus on quality control is a strong emphasis on environmentally friendly practices during production-a necessity in today’s market as companies strive for sustainable operations.

| Feature | Description |

|---|---|

| Advanced Technology | Utilization of state-of-the-art systems for galvanization ensuring quality and efficiency. |

| Skilled Workforce | A pool of local talent trained in metallurgy providing tailored solutions. |

| Quality Control | Adherence to ISO certifications with routine inspections reflecting commitment to excellence. |

| Sustainable Practices | An emphasis on environmentally friendly operations throughout the production process. |

Selecting the Right Galvanized Steel Shop

When selecting a galvanized steel shop, particularly in a bustling area like Highland Park, Texas, there are several factors to consider that will help ensure you choose the right supplier for your needs. Firstly, it is essential to assess the shop’s expertise and specialization.

Look for shops that have extensive experience and skilled workers who understand the nuances of working with galvanized steel. A shop with a proven track record in various applications can provide invaluable insight and support as you determine which products will best serve your project.

Considerations for Choosing a Galvanized Steel Shop:

- Reputation: Research online reviews and testimonials from previous clients to gauge the shop’s reliability and quality.

- Customer Service: Evaluate how responsive and helpful their team is when answering questions or discussing project specifications.

- Certifications: Check if they adhere to industry standards, which can be an indicator of quality assurance in their fabrication processes.

Understanding the types of services offered by galvanized steel shops is also crucial. Some may specialize in certain products or industries, while others might offer a broader range of options.

Whether it’s basic galvanized sheets or custom-fabricated components, confirming that the shop has the inventory or capabilities to fulfill your order efficiently can save you time and potential complications down the road. Furthermore, inquire about their turn-around times on orders; quick service can be particularly advantageous for projects with tight deadlines.

Moreover, it helps to engage in open discussions with potential suppliers about pricing, customization options, and delivery logistics. Creating clear communication channels allows for an exchange of ideas about what specific requirements or recommendations they might have based on your project needs. When visiting local galvanized steel shops in Highland Park, Texas, observe how knowledgeable staff are regarding various products and services-they should be eager to assist you in finding solutions tailored to your construction or manufacturing demands.

The Process of Galvanization

Galvanization is a crucial process that enhances the durability and lifespan of steel products by applying a protective zinc coating. This method significantly reduces the risk of corrosion, making it essential for various applications in construction, automotive, and other industries.

The galvanization process typically involves cleaning the steel surface to remove any contaminants such as rust or dirt, followed by the application of molten zinc. The interaction between these two materials forms a metallurgical bond that produces a resilient layer against environmental factors.

The impact of each step in the galvanization process cannot be understated. Firstly, surface preparation is vital for ensuring optimal adhesion and effectiveness of the zinc layer. Any residual impurities can hinder this bond and lead to premature deterioration of the galvanized steel product.

After surface preparation, the immersion in molten zinc occurs at temperatures around 450°C (842°F), where the steel undergoes an intense transformation. This step not only coats the surface but also allows for metallurgical reactions between iron in the steel and zinc, further enhancing corrosion resistance.

Environmental considerations are also pivotal when discussing galvanization processes. In Highland Park, Texas, local galvanized steel shops are increasingly adopting eco-friendly practices to minimize waste and reduce their carbon footprint during production. Many shops implement advanced filtration systems to manage emissions and recycle excess materials from their operations. Therefore, consumers seeking galvanized steel products can feel confident that many local businesses prioritize sustainability alongside quality manufacturing practices.

| Step | Description |

|---|---|

| Surface Preparation | Cleaning metal surfaces to ensure effective adhesion. |

| Molten Zinc Immersion | Dipping steel into molten zinc at approximately 450°C. |

| Metallurgical Bond Formation | Zinc reacts with iron to enhance protection against corrosion. |

| Environmental Considerations | ECO-friendly practices employed to minimize waste during production. |

Comparison of Galvanized Steel With Other Materials

When considering materials for construction and manufacturing, it’s essential to compare the advantages of galvanized steel against its primary competitors, which include aluminum and stainless steel. Each material has its unique properties that make them suitable for specific applications, but galvanized steel stands out in several key areas.

- Corrosion Resistance: Galvanized steel is particularly known for its exceptional resistance to corrosion due to the zinc coating applied during its manufacturing process. This aspect makes it ideal for outdoor applications and in environments where moisture is prevalent. In contrast, while aluminum naturally resists corrosion through oxidation, it can be less durable when exposed to certain chemicals. Stainless steel also offers impressive resistance to rust but typically comes at a higher cost.

- Strength and Durability: In terms of structural integrity, galvanized steel provides high strength-to-weight ratios that often surpass those of aluminum products. This characteristic gives it an edge when constructing frameworks or supports where weight-bearing capacity is critical. While stainless steel offers superior tensile strength, galvanized options are usually sufficient for most construction needs without breaking the bank.

- Cost-effectiveness: From a financial perspective, galvanized steel tends to be more affordable than stainless steel while offering comparable qualities. The economic advantages are clear when assessing factors such as total installation costs and long-term maintenance requirements. As a result, many businesses choose galvanized steel shops in Highland Park, Texas for their reliable products without compromising on quality or budget.

By analyzing the attributes of these materials-corrosion resistance, strength and durability, as well as cost-effectiveness-it becomes apparent why galvanized steel is a preferred choice across various industries such as construction, automotive manufacturing, and agriculture.

Conclusion and Future Trends in the Galvanized Steel Industry

In summary, the galvanized steel shops in Highland Park, Texas, represent a crucial part of both the local economy and the broader steel industry. Their significance lies not only in the diverse range of products they offer but also in their contributions to various sectors such as construction, automotive, and agriculture.

The unique geographic advantages and skilled labor pool in Highland Park further solidify its position as a thriving hub for steel fabrication. By choosing to work with local galvanized steel suppliers, businesses can benefit from high-quality products that meet rigorous standards while also supporting the regional economy.

Looking ahead, the galvanized steel industry is poised for exciting developments driven by innovation and sustainability efforts. As manufacturers adopt new technologies and refine their processes, we can expect advancements that enhance the durability and performance of galvanized steel products.

Moreover, there is a growing emphasis on environmentally friendly practices within the galvanization process itself, ensuring that steel production aligns with contemporary ecological values. This evolving landscape invites businesses and consumers alike to consider galvanized steel as a sustainable option for future projects.

For those interested in exploring what Highland Park has to offer, it’s an opportune time to connect with local galvanized steel shops. Their commitment to quality and customer service sets them apart, making it easier for clients to find tailored solutions that cater to specific needs.

As you investigate options in this vibrant community, you’ll discover not only innovative products but also a dedicated network ready to support your endeavors with expertise and excellence. Embrace the potential of galvanized steel as you explore local suppliers who continue to shape this essential industry into a more efficient and green future.